E-katalogue

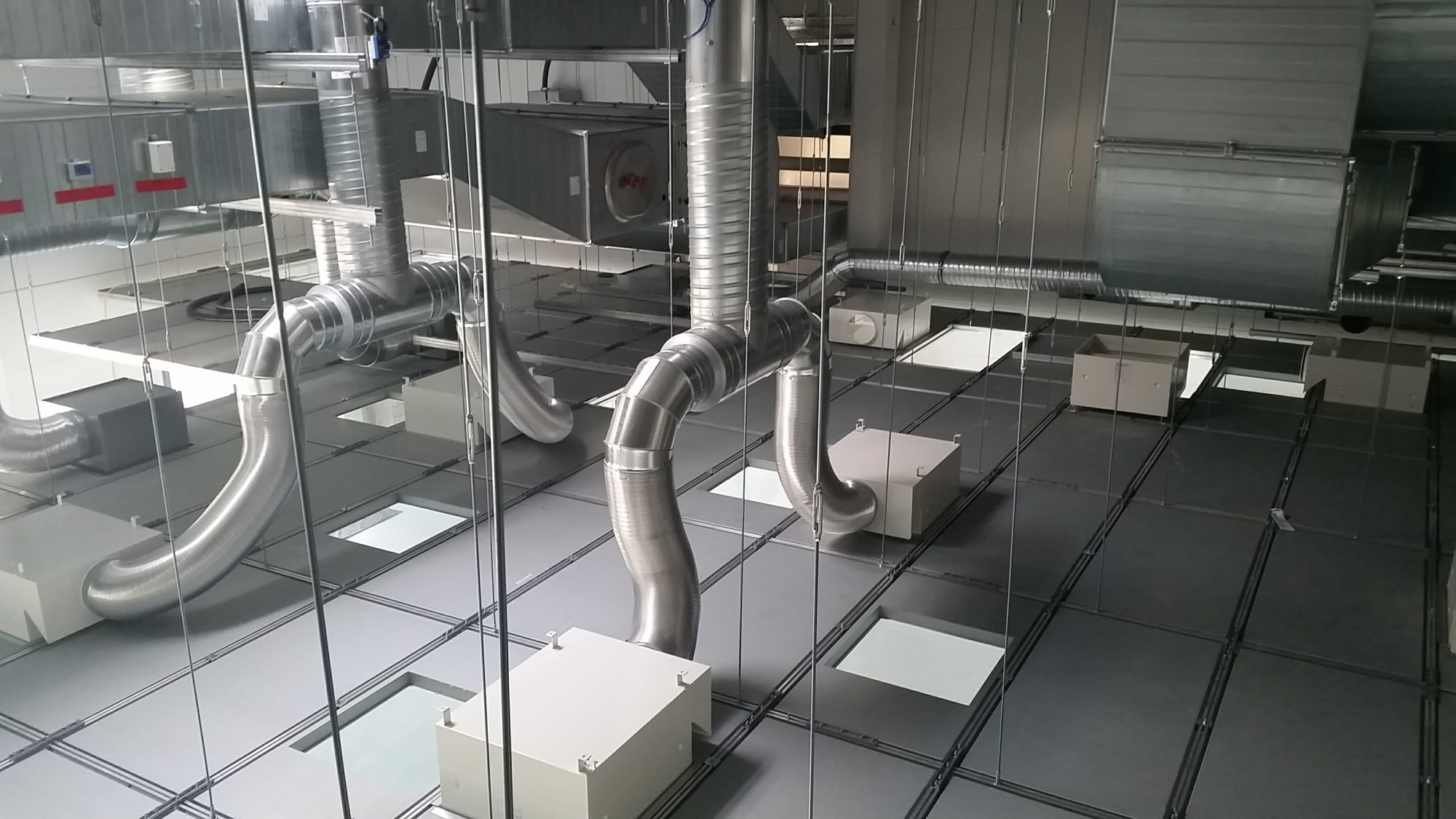

Modular suspended ceiling system 105.02

Ceiling panels are part of a self-supporting modular system consisting of load-bearing aluminium profiles and metal sheet single or sandwich panels with mineral wool filler. A limited movement of persons on the top side of the suspended ceiling is expected during installation and service work. To attach the suspended ceiling to the structural ceiling or to the suspension grid, threaded bars and suspension material are used, another anchoring option is the use of truss frame.

PRODUCT DESCRIPTION

- Sandwich or single-layer panel design.

- Placed in one plane with the profile grid in the suspended ceiling and walking side.

- Single-layer metal sheet panels are made of galvanized sheet, 1.2mm in thickness, with surface finish.

- Panels are placed into the grid from the aluminium profiles, which are suspended on the supporting ceiling structure by means of anchors and threaded bars and interconnected in the crossing points by means of connecting components.

ADVANTAGES

- You can optionally insert the panel into the suspended ceiling with a light fixture service opening, etc.

- Compared with single-layer panel suspended ceilings, sandwich panels are stronger, have significantly better thermal and noise insulation properties.

TECHNICAL DATA

| Suspended ceiling type |

|---|

| Modular ceiling system |

| Dimension | |

|---|---|

| value | dimension |

| Standard dimensions | 665 x 1360 |

| Standard dimensions | 665 x 1190 |

| Atypical dimension | XXXxXXX |

| In this section, the basic panel dimension is selected. Max. 725x1420 mm, min. 200x200 mm. | |

| Panel design |

|---|

| Standard panel, thickness 1.2mm |

| Sandwich panel |

| Atypical design |

| In this section, you can choose between two basic types of panels. Single-layer panel or sandwich panel with mineral wool filler 100kg/m3 |

| Panel type |

|---|

| 1 x Light fixture 625x625 |

| 2 x Light fixture 625x625 |

| 1 x Purofil |

| 2 x Purofil |

| Hole for Purofil and light fixture (625) |

| Panel with a service hole |

| Panel with a atypical hole |

| Atypical |

| In this section, the panel type is selected. Either the \"O\" option for standard without fitting, or for fitting the complementary components. All items are for both sandwich and single-layer panels. |

| Panel hole dimensions |

|---|

| Atypical hole size |

| Atypical hole diameter |

| Without a hole |

| Atypical - multiple holes in the panel |

| In this section, atypical hole in the panel is selected. |

| Distance of the atypical hole from the panel edge |

|---|

| Without a atypical hole |

| Length values in X (horizontal) and Y (vertical) axes determine the centre of the panel hole from the panel edge (always the bottom left corner) |

| In this section, a distance of the hole from the panel edge is chosen for an atypical panel. |

| Hue of standard panels - normally on the visible side |

|---|

| Galvanized metal sheet, hue RAL 9016 |

| Stainless steel AISI 304 |

| Powder coating (Komaxit), hue RAL |

| In this section, material and hue of the panels is selected for the bottom visible side. Standard is RAL 9016 powder coating. |

| Hue of standard panels - normally on the top side |

|---|

| Galvanized steel sheet, hue RAL 9015 |

| Powder coating (Komaxit), hue RAL |

| Galvanized steel sheet |

| In this section, the surface finish of the top walking side is selected. Galvanizing is considered standard. |

| Atypical design |

|---|

| Type design |

| Atypical design |

| Type design 0 - Unique specification out of offered versions Atypical design Q - atypical design that cannot be uniquely specified by a code |